Selective Photoheating

EXECUTIVE SUMMARY

IonoQure has developed innovative bonding processes that address the challenge of cost-optimized manufacturing of complex optical devices and large displays.

The Selective Photoheating is a new photonic technique resulting from collaboration with technology partners to precisely and effectively cure optical and structural adhesives (or coatings) in different applications, suitable for bonding all types of glass and plastic substrates.

1. PRINCIPLE AND INTRODUCTION

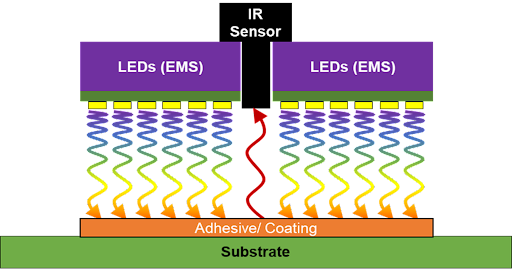

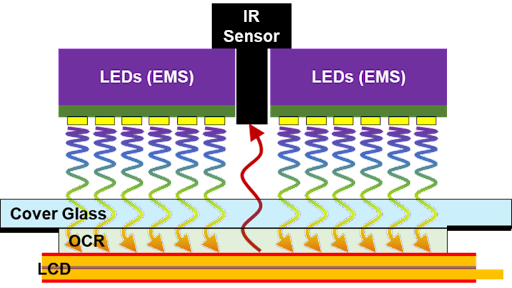

IonoQure Selective Photoheating and general Photonic Curing are innovative photonic techniques for precise and effective curing of adhesives and coatings.The principle works by using photon energy to generate the heat needed to cure or accelerate the curing of materials.

IonoQure Photoheating uses LEDs to emit a specific electromagnetic spectrum (EMS), while built-in IR sensors monitor the temperature.

2. MODES OF OPERATION

Selective Photoheating operates in two ways:

- By direct exposure of adhesives/coatings

- he adhesive is heated indirectly by irradiating the substrate in direct contact with the adhesive (e.g. under the substrate).

The schematic below illustrates the photo-heating principle in an optical display bonding application using silicone OCR.

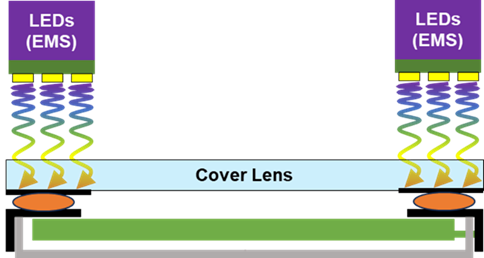

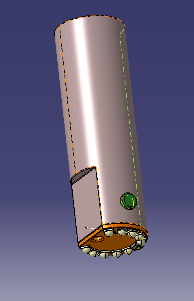

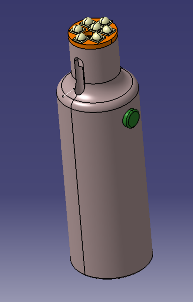

Further we also show examples of equipment used to cure adhesives in display applications:

Further we also show examples of equipment used to cure adhesives in display applications:

The LEDs used for these devices will follow certain contours and as such we can accurately define the areas where (and how much) heat is generated or not. It quickly raises the temperature to a specific target and maintains it within set upper and lower limits for a predetermined time.

The above example shows a thermoset adhesive, which reached a set temperature of 150°C in 12 seconds and maintained it for 10 seconds.

3. FEATURES AND DESIGN OPTIONS

- Device design can conform to specific shapes, and we can precisely determine which areas are heated and which are not.

- Precise monitoring and control of substrate and adhesive temperature is accomplished through the use of integrated temperature and optical IR sensors.

- The temperature range is dependent of the adhesive used and substrates.

- Typically, will be between 70°C to 150°C

- But we can achieve temperatures as high as 200°C.

- This technique is suitable for glass, plastics and especially heat sensitive materials.

4. ACKNOWLEDGEMENT

Many of our developments are supported by specialized equipment and technology partner.

5. REFERENCES AND PRIOR PUBLICATIONS

This paper may contain certain forward-looking statements, which are based on internal reports and technical information believed to be reliable.

This content or excerpts of this have been previously published.